Cement Manufacturing Process

Cement is a finely ground, non-metallic, inorganic powder when mixed with water forms a paste that sets and hardens. This hydraulic hardening is primarily due to the formation of calcium silicate hydrates as a result of the reaction between mixing water and the constituents of the cement. Cement is basic material for the building and civil engineering construction. Portland cement is the most widely used cement in concrete construction.

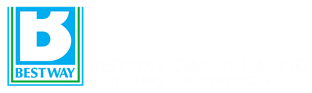

Basic Components of Portland cement

Naturally occurring deposits of Limestone & clay provides the basic raw materials for the cement manufacturing. The basic ingredients required are mentioned as under;

- Limestone (CaCO3)

- Clay (SiO2, Al2O3, Fe2O3)

- Iron Ore/Alumina Ore (Fe2O3)

- Gypsum (CaSO4.2H2O)

Dry Process for Cement Manufacturing

Dry Process is used for cement manufacturing process. The main steps involved are mentioned as under;

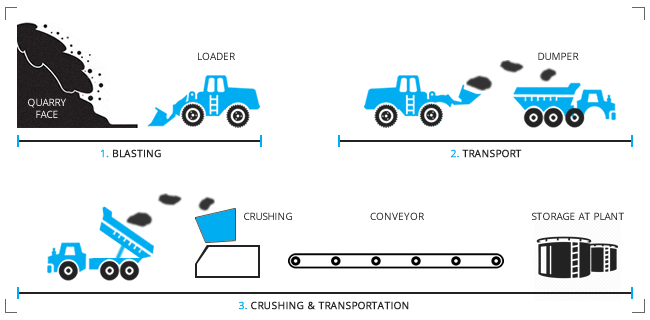

Step 1: Quarrying

Blasting: The raw material that are used to manufacture cement mainly limestone and clay are blasted from the quarry.

Transport: Material are loaded into dumpers.

Crushing & Transportation: The raw material after crushing are transported to the plant by belt conveyor. The plants stores the material before they are homogenized.

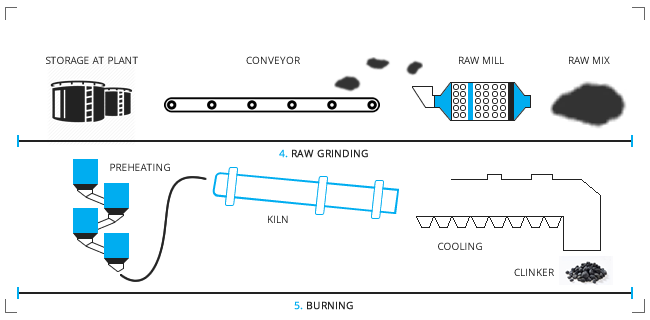

Step 2: Raw Grinding & Burning

Raw Grinding: The raw material are very finely grounded in order to produce raw mix.

Burning: The raw material is pre-heated before it goes into klin which is heated by flame that can be as hot as 2000 C. The raw mix burns at 1600 C producing clinker which is cooled rapidly after leaving from the klin with air fans. So the raw mix burnt to produce clinker; the basic material needed to make cement.

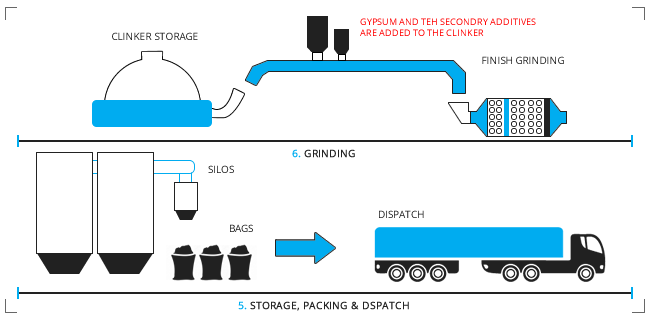

Step 3: Grinding, Storage, Packing & Dispatch

Grinding: The clinker and gypsum are finely ground giving cement.

Storage, Packing, Dispatch: The cement is stored in silos before being dispatched in bulk or in bags to its final destination.